Since 2014, CGEN has sponsored 36 capstone design projects on 4 continents. The clients for those projects are typically NGOs or private firms with a mandate for social impact in the Global South or indigenous communities in Canada. The projects emerge from consultations we hold with the organizations, in which we identify technical challenges they are facing which they may not have the time, resources, or manpower to address. Each year, teams of 4-5 students from across all engineering disciplines engage in those capstones under the supervision of CGEN-affiliated faculty.

CGEN’s unique approach considers the global context first so that technologies not only serve their purpose but are sustainable in the long-term. Site visits at the beginning of the year, enabled by generous donor funding, enable the students to understand local perspectives first-hand. Should a project advance to a stage ready for field implementation, CGEN offers support for follow-up visits and pilot testing. Our capstones often lead to follow-up projects with the same clients, garnering acclaim from students and routinely receiving awards in the Faculty’s annual showcase events. If you are interested in becoming a capstone client, please contact us for more information.

What Students Have to Say About CGEN's Capstones

This past year, I had the opportunity to participate on a capstone team that worked to develop a water filtration system for a rural community in Guatemala. This project allowed me to apply the engineering concepts I’ve learned in school to a global development context. It was without a doubt the most rewarding project that I have been a part of and was highlighted by our team’s trip to Guatemala in February. I’d like to thank CGEN for their continued guidance and expertise and for making the trip to Guatemala possible.

Anton Meier

Global Engineering capstone alumnus '20

Highlighted Projects

Harnessing Wind Power to Help Farmers in Rural Nicaragua Grow Crops in the Dry Season

Pedro Arauz is a remote agricultural community in Nicaragua characterized by high winds, deep groundwater, and a long dry season.

With no means to afford a powerful electric pump to provide water during the dry months, farmers in the region have no choice but to leave their families and seek informal, exploitative labor opportunities in the cities. This contributes to further to the village’s food and water insecurity. Recognizing this, Seeds of Learning, a local NGO, approached CGEN to ask for a technical evaluation of the options they can pursue to help the farmers during the dry season.

Over three years, CGEN Director Dr. Amy Bilton led teams of Mechanical Engineering students to automate the pumping of irrigation water from the local well by harnessing wind energy. Those projects involved numerous site visits, during which students surveyed the village to optimize its irrigation system, engaged with community members, designed the wind turbine and water lift, and worked alongside the farmers to build and install the system.

Highlighted Projects

Harnessing Wind Power to Help Farmers in Rural Nicaragua Grow Crops in the Dry Season

Pedro Arauz is a remote agricultural community in Nicaragua characterized by high winds, deep groundwater, and a long dry season.

With no means to afford a powerful electric pump to provide water during the dry months, farmers in the region have no choice but to leave their families and seek informal, exploitative labor opportunities in the cities. This contributes to further to the village’s food and water insecurity. Recognizing this, Seeds of Learning, a local NGO, approached CGEN to ask for a technical evaluation of the options they can pursue to help the farmers during the dry season.

Over three years, CGEN Director Dr. Amy Bilton led teams of Mechanical Engineering students to automate the pumping of irrigation water from the local well by harnessing wind energy. Those projects involved numerous site visits, during which students surveyed the village to optimize its irrigation system, engaged with community members, designed the wind turbine and water lift, and worked alongside the farmers to build and install the system.

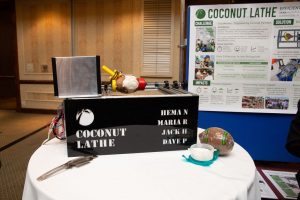

Designing a Coconut Paring Machine for a Social Enterprise in the Philippines

Almost 15 million Filipinos depend on coconuts for their livelihood. Many live in poverty and the vast majority are in debt. In large part, this is due to the fact that many of those farmers are forced to sell their coconuts in the form of Copra, a low-value product. To help those farmers, CocoAsenso established a small factory in in the heart of Samar Island, which processes coconuts for those farmers into high-value dessicated coconut. The factory also offers the farmers employment opportunities to supplement their farming income.

Among the many steps involved in coconut processing, the most laborious task involves paring a thin layer surrounding the coconut meat known as the testa. When CocoAsenso reached out to CGEN, this task was being fulfilled by four women, who would spend most of the day carrying out the paring. This led to some repetitive strain injuries and small cuts among the workers, and it was generally known to be one of the slowest processing steps. To remedy the problem, a capstone team was asked to design a paring machine that can help speed up the process so its throughput can match the rest of the factory and minimize injuries to the operators.

Starting with a state of the art search, students explored all options that exist for rapidly paring starchy layers off of fruits and nuts. After numerous consultations with the client, it was decided to pursue a design involving a rotating vice and a knife with a wide handle. To verify the suitability of the device, the students traveled to the Philippines to meet withe line workers, collect information, and refine their design. Upon their return, they completed the design and proceeded to pitch it at the annual capstone showcase where they won the Best Design award.

Powering a Digital Learning Lab with Off-Grid Solar Technology in Kenya

Despite the Kenyan government’s ambitious target to increase electricity connectivity from the current 15% to at least 65% by the year 2022, many still live without power. A rural primary school located in Kirindon, Kenya hopes to implement a digital learning program to enhance the quality of education. World Vision Canada has established an Information Communication Technology (ICT) lab in this off-grid school, and is performing pilot tests of their digital education system at schools in remote areas of Kenya that have on-grid charging systems.

The lab consists of 30 tablets, a Raspberry Pi (server) and its associated battery. The capstone group’s goal was to establish a method of powering the lab. The primary objectives were simplicity for both use and implementation, operation, maintainability/troubleshooting, robustness, safety and scalability. The budget allocated was $CAN 2,500. When comparing all available electricity generating technologies, PV solar technology was selected due to how well the technology exploited the service environment. After determining that the system would be fully Direct Current (DC) based, the team went ahead with an inverter-less Balance of System (BOS) design. The daily energy requirement was calculated to be approximately 1215Wh. The storage capacity of the system was then calculated by accommodating for consecutive cloudy days, prolonging battery life by regulating depth-of-discharge of the battery bank, and accounting for temperature variations in the space. This storage capacity of the battery bank was calculated to be 5,208Wh. The system consists of a 300W solar panel, a charge controller, a battery bank with four AGM deep-cycle golf cart batteries, a terminal block and three custom modified 10-port USB charging stations.

Along with the electrical system, a scalable mounting structure and power box (cabinet) housing internal components was finalized. The team proceeded with testing a prototype with 4 tablets, two 7-port USB charging stations, a single AGM battery and a 300W panel to more accurately determine efficiency values, model the charging profiles of the battery and devices, and to confirm the energy requirement. Due to the constant issue of measuring an accurate State-Of-Charge of the battery with the charge controller, a different model along with a battery management system was added to the final design. Through testing, the team learned the behaviour and efficiency of the different components and accounted for them in a revised load energy requirement of 1194Wh and the final design. The team also created an implementation and troubleshooting manual to aid the users in installing and maintaining the system. The project was completed at $1,951.18. If successful, WV would look to scale this system over multiple schools in other regions of Africa and other parts of the world.

An Improved, Portable Sandbagging Machine for Rapid Flood Response

GlobalMedic is a Toronto-based humanitarian relief organization which responds to emergency crises across the world. As the client for this capstone, they tasked a team of four upper-year Mechanical Engineering students at the University of Toronto with improving the method of filling sandbags in flood response situations.

With no means to afford a powerful electric pump to provide water during the dry months, farmers in the region have no choice but to leave their families and seek informal, exploitative labor opportunities in the cities. This contributes to further to the village’s food and water insecurity. Recognizing this, Seeds of Learning, a local NGO, approached CGEN to ask for a technical evaluation of the options they can pursue to help the farmers during the dry season.

Currently, the client has access to two different sandbagging methods:

The first involves manually filling sandbags using shovels, a laborious, physically demanding process which results in only 12 bags filled per hour per person. Its advantage, however, is that these bags can be filled close to the site in which the sandbag wall is being built, cutting down on transit time. The second option involves using a sandbagging machine, such as the Multibagger, which can fill 1,000 bags per hour with only 3 volunteers. While this machine offers a rapid, efficient response, it is logistically challenging and time-consuming to transport to site.

The design team was able to come up with a design that cuts down on that transportation distance, saving valuable time in disaster situations, while reducing the amount of physical labor required throughout the process. They developed a conversion kit that turns a traditional snowblower into a mobile sandbagging machine. Using the preliminary prototype that the design team built, it would take 18 sandblowers to output the same number of bags as the Multibagger.